1. Seasonal Concrete Expansion

Massive dams are designed with the understanding that concrete expands in heat and contracts in cold. Seasonal temperature changes can cause a dam to subtly lengthen or shrink by millimeters or even centimeters across its entire structure. Engineers account for this by building expansion joints into the design, allowing sections to move independently without cracking. These changes are closely monitored using sensors embedded deep within the concrete. In colder months, the structure tightens slightly, while warmer seasons allow it to relax outward. This slow breathing of the dam happens year after year and is considered completely normal. Without this planned flexibility, temperature stress could lead to serious structural damage over time.

2. Reservoir Weight Pressure

When a reservoir fills, the sheer weight of billions of tons of water presses against the dam and the ground beneath it. This pressure causes the structure to lean microscopically downstream and compress the rock foundation below. As water levels drop during dry seasons or controlled releases, that pressure eases, allowing the dam to shift back. These movements are tiny but measurable, often tracked with high-precision instruments. Engineers expect this response and design dams to handle constant changes in load. The ability to flex under pressure helps prevent cracking and structural fatigue, ensuring the dam remains stable even during extreme water fluctuations.

3. Foundation Rock Compression

Even the hardest bedrock beneath a dam is not perfectly rigid. Over time, the immense weight of the structure and its reservoir slowly compresses the rock below. This gradual settling can cause a dam to sink by small but measurable amounts, often occurring over decades rather than years. Engineers study the geology of a site extensively before construction to predict how much compression will occur. Monitoring systems track vertical movement to ensure it stays within safe limits. Rather than being a warning sign, controlled foundation compression is expected behavior and factored into the dam’s long-term stability calculations.

4. Earth’s Subtle Movements

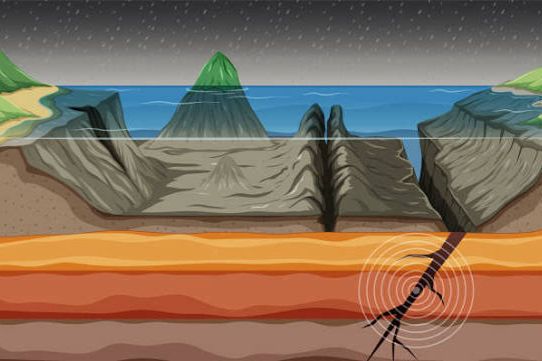

The Earth itself is always moving, even in regions without major earthquakes. Tectonic plates shift slowly, and dams must accommodate these gradual changes. Many large dams are equipped with seismic sensors that detect tiny ground movements invisible to humans. These shifts can cause slight horizontal or vertical adjustments in the structure over time. Engineers use this data to assess stress distribution and confirm the dam is responding as expected. In seismically active areas, flexibility is a critical safety feature. A dam that can subtly move with the Earth is far more resilient than one designed to remain perfectly rigid.

5. Hoover Dam Flexing

Hoover Dam is one of the most studied examples of controlled dam movement. Built in the 1930s, it was designed to cool and contract gradually as its massive concrete blocks cured. Engineers predicted it would take decades to fully settle, and that prediction proved accurate. Even today, the dam expands slightly during hot desert summers and contracts during colder months. These movements are carefully measured and remain well within safe limits. Hoover Dam’s long history shows that slow, predictable motion is not a weakness but a sign of sound engineering.

6. Gravity Dam Design

Gravity dams rely on their enormous weight to resist water pressure rather than internal reinforcement alone. Because of this, they are designed to flex slightly under load rather than remain completely rigid. The dam’s mass presses downward and outward, counteracting the force of the reservoir. Small shifts occur as water levels change, distributing stress evenly across the structure. This design philosophy has been used successfully for over a century. By allowing minor movement, gravity dams reduce the risk of sudden cracking or failure, proving that controlled flexibility is essential to long-term durability.

7. Arch Dam Elasticity

Arch dams are thinner and more curved than gravity dams, relying on their shape to transfer water pressure into the canyon walls. This design allows them to flex slightly like a bow under tension. As reservoir levels rise, the arch tightens against the rock sides, moving just enough to distribute stress safely. When water levels fall, the structure relaxes. Engineers carefully calculate these movements during design and construction. The elasticity of arch dams makes them efficient and strong, especially in narrow valleys, while still accommodating constant environmental changes.

8. Temperature Monitoring Systems

Modern dams are filled with sensors that track temperature changes deep inside the concrete. These systems help engineers understand how heat affects expansion, contraction, and internal stress. Data is collected continuously and compared against expected behavior models. If readings fall outside normal ranges, engineers investigate long before any visible damage occurs. This constant monitoring allows dams to safely accommodate movement rather than resist it. Temperature data has become one of the most valuable tools in dam safety management, ensuring subtle shifts remain predictable and harmless.

9. Long-Term Concrete Creep

Concrete does not behave like stone; it slowly deforms under sustained pressure in a process known as creep. Over decades, the weight of a dam and its reservoir causes gradual shape changes at a microscopic level. Engineers factor this into designs using long-term material testing and predictive models. Creep occurs very slowly and is carefully monitored to ensure it does not compromise stability. Rather than being a defect, controlled creep helps relieve internal stress, allowing the structure to adapt over time without sudden failure.

10. Laser Alignment Tracking

Some of the most precise measurements of dam movement come from laser alignment systems. These tools can detect shifts as small as a fraction of a millimeter across massive structures. Engineers use fixed reference points to track how a dam moves in response to temperature, water pressure, and geological changes. The data confirms whether movement matches design expectations. This technology provides reassurance that subtle flexing is normal and controlled. Laser monitoring has become a standard part of modern dam safety programs worldwide.

11. Reservoir-Induced Tilting

As a reservoir fills and empties over time, the uneven pressure exerted on a dam can cause slight tilting, often measured in millimeters. This phenomenon is well documented in large dams worldwide and is considered during the design phase. Engineers install inclinometers and deformation gauges to track even the smallest angular changes. These movements usually occur gradually as water loads shift seasonally or during long-term operational changes. The key factor is predictability. As long as the tilt remains within expected parameters, it poses no risk. In fact, monitoring this subtle leaning helps engineers better understand how the structure interacts with its environment, reinforcing confidence in its long-term stability.

12. Constant Safety Surveillance

Behind every major dam is a continuous safety monitoring effort that never truly stops. Engineers routinely analyze data from motion sensors, pressure gauges, seismic instruments, and visual inspections to track how the structure moves over time. These observations confirm that small shifts are behaving exactly as predicted. International dam safety standards emphasize long-term surveillance rather than expecting total stillness. This approach allows operators to detect unusual behavior early and respond long before it becomes dangerous. The quiet, ongoing observation of dam movement is one of the most important reasons these massive structures continue to operate safely for decades.

The idea that dams must remain perfectly still is a myth. Their strength lies in their ability to flex, settle, and adapt to natural forces in slow, controlled ways.

Like this story? Add your thoughts in the comments, thank you.