1. Starting out in a leaky shed

The semiconductor world is a bit like a high stakes puzzle where most of the pieces are invisible to the naked eye. At the center of this puzzle sits ASML, a Dutch company that many people had not even heard of a decade ago, but today, they are the only ones capable of making the machines that power our smartphones and AI dreams. Getting to this level of global dominance was not an accident or a stroke of luck; it was the result of a series of gritty, sometimes risky choices made in quiet boardrooms and messy labs. Looking back, these eighteen turning points show how a small underdog outpaced giants by betting on the impossible and sticking to their guns when everyone else told them to pack it up. It is funny to think about now, but ASML did not start in a high tech lab; it basically started in a leaky wooden shack.

Back in the eighties, Philips and ASM International teamed up, but nobody really thought they would make it. They were the scrappy underdogs up against Japanese giants who had all the money in the world. The big decision here was simply choosing to stay in the game when things got tough. Instead of trying to do everything, they focused on one thing: how to use light to draw patterns on silicon. It was not glamorous, and for a long time, it was not even profitable, but that stubbornness to keep the lights on in that shed is exactly why your phone is as powerful as it is today. They chose the difficult path of lithography when others were comfortable with the status quo. This small team decided to focus entirely on the precision of light, building the world’s most accurate clock while everyone else was trying to tell time.

2. Trusting the neighbors

You would think a massive tech company would want to build everything themselves to keep secrets, but ASML did the opposite. They decided early on to trust other specialists, like Zeiss for lenses. It is a bit like a chef deciding not to grow their own vegetables so they can focus entirely on the cooking. This created a weirdly close knit family of companies where everyone’s survival depended on each other. One long time observer mentioned that ASML is more of an architect than a builder, coordinating a symphony of suppliers. This openness meant they did not have to be experts at everything; they just had to be the best at bringing the world’s best pieces together in one box. It was a strategy based on deep mutual respect and the understanding that no one can win alone.

This trust based model meant that when technical hurdles popped up, they had the world’s best minds already in the room helping them solve the problem, rather than fighting over contract details or pricing. One thing that really sets ASML apart is how they decided to treat their suppliers as family rather than just vendors. Early on, they realized they could not build every single part of a machine that has hundreds of thousands of components. Instead of trying to own everything, they formed deep, locked in partnerships with companies like Zeiss for lenses and Trumpf for lasers. This created a network where everyone’s success was tied together. This level of industry wide collaboration is rare, but it proved that when the stakes are high enough, even the fiercest competitors will chip in to make sure the future happens.

3. A massive gamble on invisible light

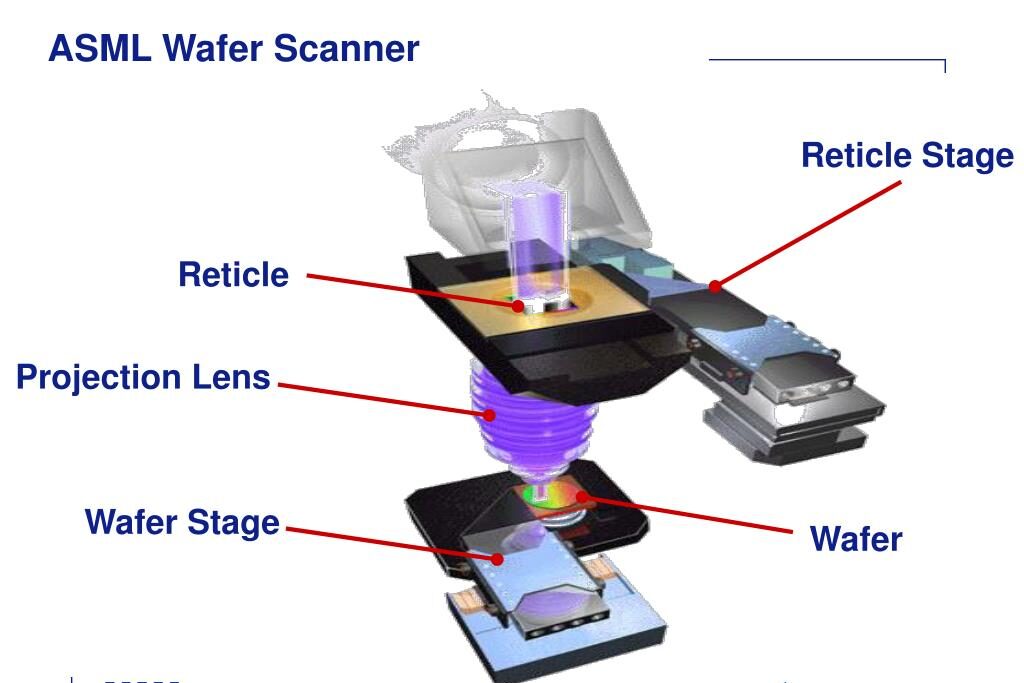

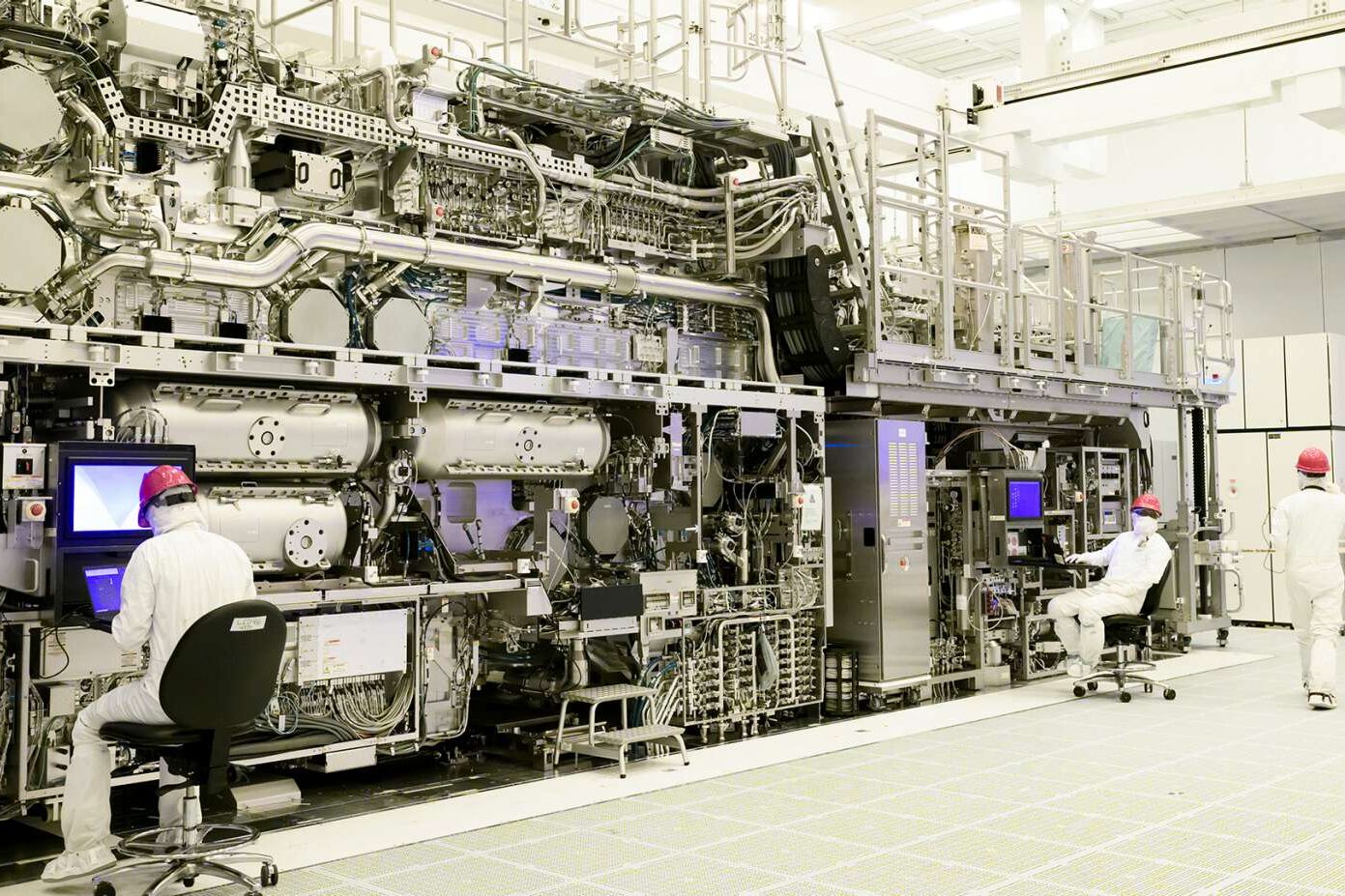

There was a point where the industry hit a wall, and everyone said that we cannot make chips any smaller. ASML disagreed and decided to chase Extreme Ultraviolet light, or EUV. This stuff is so hard to work with that it is absorbed by almost everything, including air. It was a multi billion dollar bet on something that many physicists said was practically impossible. While their rivals at Nikon and Canon looked at the price tag and the physics and said no thanks, ASML doubled down. They spent twenty years and a mountain of cash failing until they finally got it right. It is the ultimate hold my beer moment in tech history, and it is the reason they have zero competitors left for the high end stuff today. This gutsy call changed everything.

This required creating a light source by hitting drops of molten tin with a high power laser twice, fifty thousand times a second. It sounds like science fiction, and for a long time, it felt like it. While competitors eventually gave up on EUV because it was too expensive and complicated, ASML kept pouring billions into research. This persistence created a moat so wide that, today, they are the only company on the planet that can produce these machines, making them the ultimate gatekeepers of high end tech. Back in the late nineties, the industry knew they would eventually hit a wall with how small they could shrink chips. ASML made the gutsy call to pursue EUV light, a technology so difficult to harness that many experts called it a physics nightmare that would never see the market.

4. Getting the customers to pay the bills

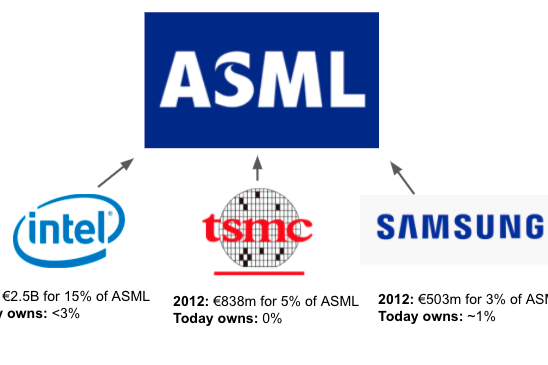

In 2012, ASML ran into a problem where the research for the next generation of machines was so expensive it was going to bankrupt them. So, they did something incredibly gutsy and they asked their biggest customers, like Intel and Samsung, to buy a piece of the company and fund the research and development. Imagine a car company asking you to pay for the development of a new engine before you can even buy the car. It sounds crazy, but it worked. It turned their customers into partners. As one tech analyst put it, they did not just sell a machine; they sold a shared destiny. This move made sure that when the tech was finally ready, the world’s biggest chipmakers were already standing in line waiting for delivery.

It was a brilliant move because it did not just provide cash; it ensured that the biggest chipmakers in the world were literally invested in ASML’s success. If the technology failed, they all lost. This created a guaranteed market for the machines before they even existed. It turned a high-risk gamble into a collective mission. This level of industry wide collaboration is rare, but it proved that when the stakes are high enough, even the fiercest competitors will chip in to make sure the future actually happens. In 2012, ASML did something totally unheard of when they launched a co investment program where Intel, Samsung, and TSMC actually bought stakes in the company. This ensured that the industry’s leaders were committed to the long-term success of the project.

5. Making the machines easy to fix

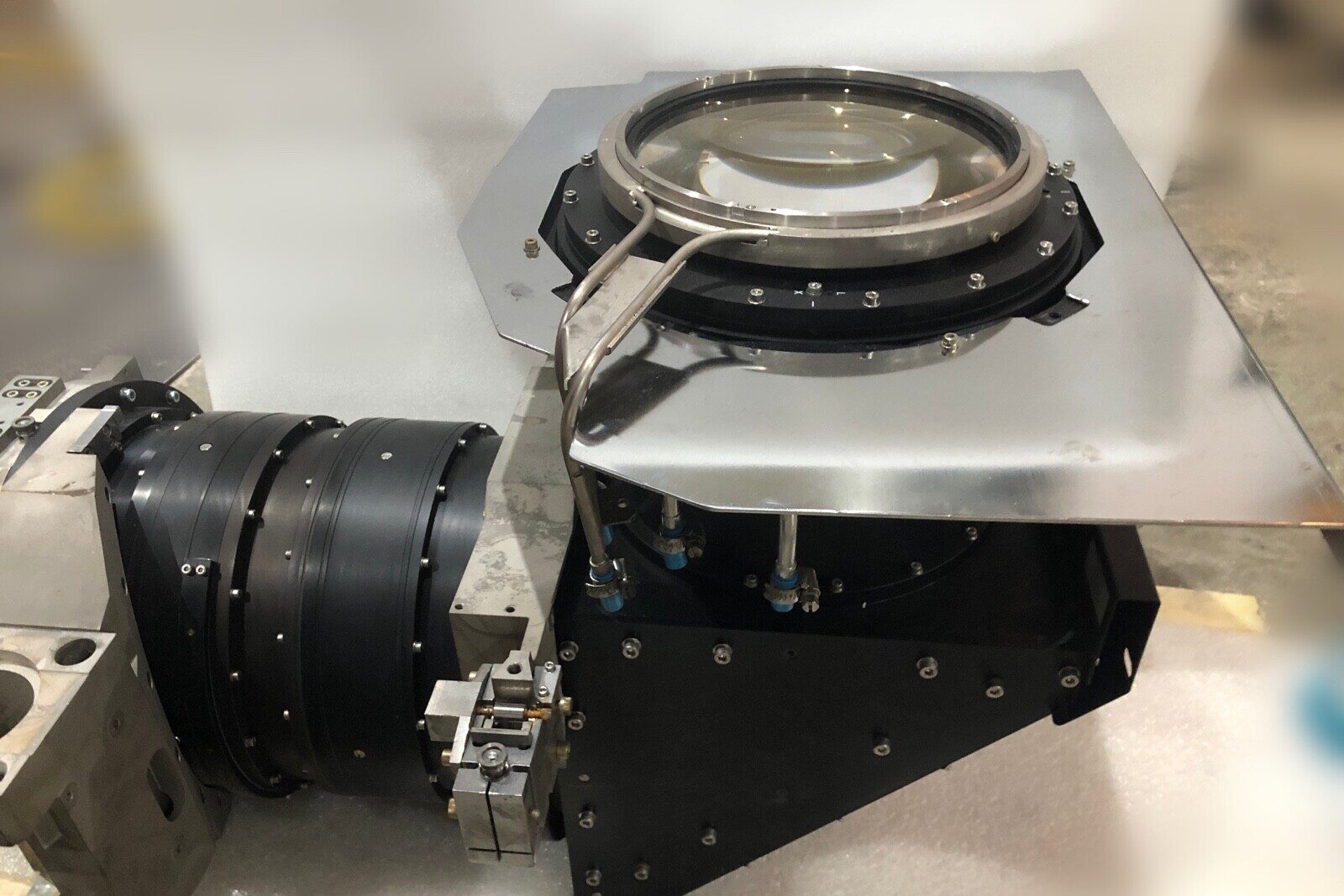

When you are selling a machine that costs as much as a private jet, you cannot afford for it to be down for a week because of a broken screw. ASML made a very practical, human decision to build their systems in blocks or modules. If something goes wrong, you do not have to take apart the whole three story machine; you just swap out the faulty module. It is like being able to change a car’s engine in ten minutes during a pit stop. This kept their customers happy because time is literally money in a chip factory. It also meant they could keep upgrading parts of the machine without making the whole thing obsolete, which is a rare bit of common sense in the high tech world.

This design philosophy made their machines more reliable and cost effective over the long run, proving that being practical is just as important as being innovative when you are dealing with the world’s most complex hardware. When you are building a machine the size of a double decker bus that costs two hundred million dollars, you have to think about maintenance. ASML decided early on to build their systems using a modular approach. This means if one specific part breaks or needs an upgrade, you do not have to scrap the whole machine; you just swap out the module. This was a game changer for chip factories that run twenty four seven because it minimized downtime and allowed for constant improvement over many years of heavy operation.

6. Using a literal water trick

Before the big EUV breakthrough, the industry was stuck again. ASML engineers had a Eureka moment when they asked what if we put a drop of water between the lens and the chip? This is called immersion lithography. The water bends the light better than air, allowing for much finer detail. Their competitors thought it was a gimmick and stayed with dry machines. But the water trick worked perfectly. It was a simple, elegant solution to a massive problem. It gave ASML a huge lead while everyone else was trying to figure out more complicated ways to shrink transistors. Sometimes, the most high tech solution is actually just a very clever use of a bit of liquid that others ignored in their designs.

Around 2003, the industry was stuck. ASML decided to put a layer of water between the lens and the silicon wafer to refract light and create even smaller patterns. It sounded crazy putting water inside a high precision machine, but it worked beautifully. This decision allowed them to leapfrog their Japanese competitors who were betting on a different, more complicated dry technology. By making the simple but brilliant choice to use water, ASML gained a massive lead in the market. It is a classic example of finding an elegant, unexpected solution to a problem that everyone else was trying to solve with brute force and more expensive hardware. This choice solidified their position as the leading innovator in the semiconductor equipment industry worldwide.

7. Staying home in Veldhoven

You see a lot of tech companies move their headquarters to flashy places like San Francisco or London once they get big. ASML stayed right where they started in the Netherlands. This was a deliberate choice to keep their tribal knowledge in one place. By staying in Veldhoven, they kept their engineers close to the local universities and long term suppliers. It created this massive brain trust where people have worked together for thirty years. This kind of deep, personal connection is something you cannot just buy or move to a different country. It is the secret sauce that keeps their culture grounded and focused on the long game rather than just next quarter’s stock price and financial results or hype.

In a world where big tech companies often move to Silicon Valley or cheap manufacturing hubs, ASML stayed put in Veldhoven. This was not just about loyalty; it was a strategic choice to stay close to their core engineering talent and their long term partners. This local concentration created a Brainport region where everyone knows everyone, and knowledge flows freely between the university, the company, and the suppliers. By keeping their roots deep in Dutch soil, they maintained a unique company culture that values directness and collaboration. This stability has been a secret weapon, as it allowed them to build decades of institutional knowledge that is almost impossible for a newcomer to replicate, no matter how much venture capital they might have.

8. Perfectionism that borders on crazy

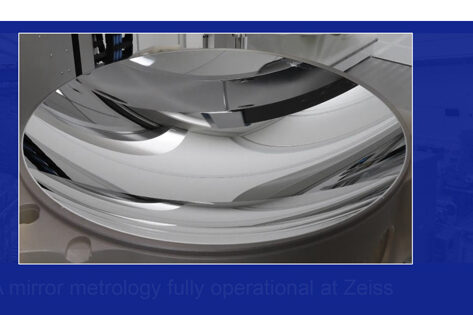

To make EUV work, ASML needed mirrors that were essentially perfect. We are talking about surfaces so smooth that if you expanded them to the size of the United States, the biggest bump would be the height of a blade of grass. They pushed their supplier, Zeiss, to achieve this impossible standard. It was not just a business deal; it was a decades long obsession with quality. This decision to never say good enough is why their machines work. They realized that when you are dealing with things at the atomic level, there is no room for error. This drive for perfection forced their entire supply chain to become the most precise manufacturing network in human history, setting a new global standard for engineering.

They did not just buy mirrors; they worked with Zeiss to create mirrors that are the smoothest surfaces ever made by humans. By demanding this level of perfection, they forced their entire supply chain to level up. This was not just about being a tough customer; it was about realizing that the machine is only as good as its weakest link. Their ability to manage these incredibly precise technical requirements across hundreds of different companies is what makes them a system integrator extraordinaire, turning raw physics into a working production line. One of the most overlooked decisions was ASML’s obsession with controlling the quality of light. They realized that the success of the entire project rested on the quality of these optics.

9. Realizing software is just as important

Most people think of ASML as a hardware company since after all, they build these massive, one hundred eighty ton machines. But a key decision they made was to become a software powerhouse, too. They realized that even with perfect hardware, the light still behaves in weird ways. They bought a company called Brion to help them use math to pre distort the images so they come out perfect on the chip. It is a bit like wearing glasses that correct your vision before you even look at something. By weaving complex algorithms into the physical machine, they made it impossible for anyone else to just copy the hardware and get the same results in the factory or the lab.

This allowed them to trick the light into printing features even smaller than the wavelength of the light itself. It is a bit like using digital magic to sharpen a blurry photo. By integrating software so deeply into their hardware, they made their machines more capable and harder to copy, adding another layer of protection to their market position and helping their customers get more out of every wafer. Modern lithography is not just about shining light; it is about using complex algorithms to correct for tiny distortions and errors in real time. This decision to invest heavily in software early on was a stroke of genius that separated them from other traditional manufacturing companies in the electronics industry.

10. Letting the world help out

ASML has this open door policy when it comes to ideas. Instead of hiding in a basement, they work closely with research centers like IMEC in Belgium. They figured out that the problems they were solving were so big that no one company could do it alone. By sharing some of their challenges with academics and researchers, they got a fresh perspective on their tech. This open innovation kept them from getting tunnel vision. It is a very humble way to run a giant company by admitting you do not have all the answers and being willing to listen to a PhD student with a weird idea that might just work perfectly when applied to a global problem.

By sharing some of their challenges with the broader scientific community, they got access to a global pool of talent and ideas. This keeps them at the cutting edge without having to shoulder the entire burden of basic research alone, making the path to the next generation of chips a little less lonely. ASML has always been very open about the fact that they do not know everything. They actively collaborate with research institutes to test out new ideas years before they become commercial products. This decision to embrace open innovation meant they were never working in a vacuum. They were always tuned into what the next five to ten years of the industry would look like.

11. Keeping their independence

Over the years, many bigger companies probably wanted to buy ASML. But they stayed independent, and that was a massive win. Being an independent arms dealer means they can sell to everyone including Intel, TSMC, and Samsung without anyone worrying about a conflict of interest. If they were owned by one of those companies, the others would never trust them with their secrets. This independence gave them the freedom to make their own mistakes and, more importantly, their own breakthroughs. They answer to the technology and their customers, not to some distant corporate parent who might have cut their budget the moment things got difficult or expensive or when quarterly profits dipped below expectations.

This independence was vital because it allowed them to serve all chipmakers equally without the baggage of being owned by a competitor. By remaining a neutral arms dealer in the chip wars, they became a trusted partner to everyone. This independence gave them the freedom to make long term research bets that a parent company might have killed off during a bad quarter, ensuring their survival. Throughout the 90s and 2000s, there were many opportunities for ASML to be swallowed up by a bigger electronics conglomerate. However, the leadership fought to keep the company independent. This was a critical choice that protected their unique culture and their ability to innovate without any outside interference or bias.

12. Measuring twice and cutting once

In the world of chips, if you are off by even a hair, the whole thing is junk. ASML decided to stop just being the printer and started being the ruler too. They invested heavily in metrology, which is basically the science of measuring things really accurately. Their YieldStar machines check the work of the lithography machines in real time. This means the factory can catch a mistake before it ruins thousands of chips. It is like having a printer that tells you when the ink is slightly blurry so you can fix it immediately. This focus on measurement made their machines much more valuable to customers who hate wasting money on bad silicon wafers or lost production time.

By building measurement tools directly into their lithography process, they allowed chipmakers to catch errors instantly. This holistic lithography approach means they are not just selling a printer; they are selling a system that checks its own work. This reduces waste for their customers and makes the ASML machines even more indispensable. It is about providing the peace of mind that comes with knowing every single one of the billions of transistors is exactly where it is supposed to be. A machine is only useful if you know it is working correctly, which is why ASML’s decision to buy YieldStar and focus on metrology was so smart. It turned a simple machine into a complete factory solution.

13. Pushing the limits again with High NA

Just when the world finally got used to EUV, ASML decided to change the game again with High NA EUV. These new machines are even bigger and more expensive, but they allow for even tinier features on a chip. A lot of people asked if this was really necessary. ASML’s answer was a resounding yes. They know that the moment they stop pushing, the progress of technology stalls. By starting on this new version before the old one was even fully finished, they stayed five steps ahead of everyone else. It is a relentless pace, but it is the only way to keep making the chips that power things like AI and autonomous vehicles.

Each of these new machines costs over three hundred fifty million dollars and requires a complete rethink of factory layouts. By pushing the limits of what is physically possible, they ensure that Moore’s Law stays alive. It is a bold statement that they are not finished yet. As one analyst puts it, ASML is the only company with the roadmap to the future, and they are currently building the road themselves. Even after conquering EUV, ASML did not sit back. They are already rolling out High NA EUV, which uses even larger optics to achieve higher resolution. The decision to start working on this while the first EUV machines were barely functional shows their relentless drive.