1. Introduction: The Factory Behind Everything

Most people use high-tech gadgets every day without ever stopping to wonder where the “brains” of these devices actually come from. From the smartphone in your pocket to the medical equipment in hospitals and even complex military hardware, almost everything depends on a silent chain of precision. At the very heart of this global system is the Taiwan Semiconductor Manufacturing Company, commonly known as TSMC. Founded in 1987 by Morris Chang, the company has grown from a small government-backed project into the most important chipmaker on the planet.

What makes TSMC truly remarkable is not just its massive size, but its quiet and deliberate way of doing business. While other tech giants chase headlines with flashy product launches, TSMC focuses on long-term stability and discipline. It operates with an almost obsessive attention to detail that ensures the world’s digital economy stays upright. Since the early 1990s, the company has proven that being consistent is more important than being loud. These quiet choices explain how a single firm on a small island became the backbone of modern life. Without their steady hand, the technology we rely on would likely fail. This look inside their strategy shows how a mindset of “boring” reliability actually changed the entire world forever.

2. Foundry First

One of the most important decisions in tech history happened in 1987 when TSMC decided it would never design its own chips. At the time, most companies both designed and built their hardware, which often led to messy legal battles and stolen ideas. By choosing to be a “pure-play” foundry, TSMC promised its customers that it would only manufacture their designs and never compete against them. This choice removed a huge conflict of interest and built a level of trust that other companies simply could not match. It allowed designers to share their most secret blueprints without fear.

Over the last few decades, this clear focus attracted massive clients like Apple, Nvidia, and AMD. These brands felt safe pushing the limits of innovation because they knew their manufacturing partner wasn’t trying to copy them. Because TSMC didn’t have to worry about marketing consumer products, they could spend all their energy refining the actual making of the chips. This unique culture rewards engineers for making the factory more reliable rather than creating flashy breakthroughs. Today, this model has turned TSMC into a piece of global infrastructure rather than just a regular company. It acts as a neutral ground where the greatest tech minds can bring their ideas to life with total confidence.

3. Relentless Capital Spending

TSMC is known for spending more money on equipment and factories than almost any other business on Earth. Even when the global economy slows down, the company continues to pour billions of dollars into its facilities. For example, in 2021, they announced a massive $100 billion investment plan over three years to meet the rising demand for chips. This behavior might look risky to some, but it is exactly what keeps them ahead of the competition. By spending money during recessions, they ensure they are ready for the next big wave of technology before anyone else.

Advanced chipmaking requires years of planning, so pausing investment for even a few months can cause a company to fall behind for years. TSMC’s leadership understands that gaps in spending give rivals a chance to catch up. This long-term view gives their customers a huge sense of security. When a company like Apple plans a new iPhone years in advance, they need to know the factory will have enough space and mac

hines ready to build millions of units. TSMC’s willingness to spend big signals a level of stability that encourages designers to take bigger risks with their technology. This constant growth has turned their factory sites into some of the most expensive and advanced locations in human history.

4. Manufacturing Over Marketing

Unlike many Silicon Valley giants, TSMC spends almost nothing on fancy commercials or public relations. You won’t see their logo on billboards or find their executives giving high-energy speeches at tech conferences. This is a very deliberate choice. The company believes that high-quality results speak much louder than any advertising campaign ever could. Because their customers are famous global brands, TSMC prefers to stay in the shadows and let the finished products do the talking. This lack of ego is a core part of their corporate DNA and overall success.

Internally, this philosophy keeps the focus where it belongs: on the factory floor. Money that other companies might waste on marketing is instead used to train staff and upgrade precision tools. Engineers are encouraged to focus on tiny, incremental improvements that reduce defects rather than chasing “cool” features that might not work. This quiet competence is a huge part of why clients stay loyal for decades. In an industry where a single week of delay can cost billions of dollars, predictability is the most valuable trait a partner can have. TSMC has proven that you don’t need a famous brand name to be the most important player in the room; you just need to be the most reliable.

5. Yield Before Speed

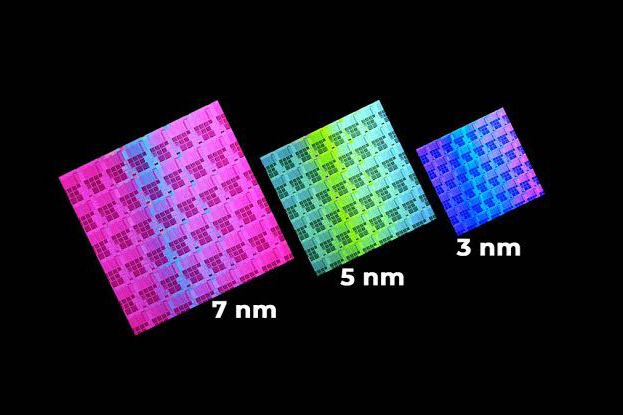

In the high-stakes race to make chips smaller and faster, many companies rush new technology to the market before it is actually ready. TSMC takes a different path by prioritizing “yield,” which is the percentage of working chips on a single silicon wafer. They believe that being the absolute first to launch a new process is useless if half the chips are broken. This conservative approach means their production runs are much more stable and cost-effective. A chip that works 95% of the time is far more valuable to a business than a faster one that only works 60% of the time.

This focus on reliability helps prevent expensive disasters for their customers. When TSMC rolls out a new generation of technology, such as the move to 3-nanometer chips in 2022, they make sure the process is mature and predictable. This discipline reduces the risk of bad surprises during a major product launch. Because they have a track record of delivering what they promise, top designers are more willing to bet their entire company’s future on TSMC’s factories. By choosing stability over raw speed, they have built a reputation for excellence that makes them the safest bet in a very risky industry. It is a slow and steady strategy that has allowed them to dominate the market.

6. Deep Customer Integration

TSMC does much more than just take orders and ship boxes of hardware. They actually embed their own staff into the design teams of their clients. This collaboration starts years before a chip is ever built, allowing engineers to fix problems while the product is still just a drawing. By working together so closely, they can make sure a design is easy to manufacture without losing any of its power. This partnership saves a massive amount of time and money by preventing errors that would normally only show up once production begins.

This deep level of teamwork creates a bond that is very hard for competitors to break. When a client has spent five years co-developing a process with TSMC, they are very unlikely to switch to another factory. It isn’t just about a legal contract; it is about the shared knowledge and trust they have built together. The factory essentially becomes an extra limb of the customer’s own engineering department. This relationship allows for a smooth flow of information that helps both sides succeed. While consumers only see the final gadget, the secret to its success is often this invisible, long-term cooperation. This integration acts as a “moat” that protects TSMC from rivals who try to win over their customers with lower prices.

7. Talent Above All

At TSMC, engineering talent is treated as a vital national treasure rather than just a group of employees. The company focuses on hiring people for their long-term potential and rewards those who stay for their entire careers. Many of the top leaders have been with the firm since its early days in the late 1980s and 1990s. This creates a deep pool of “institutional memory” that is impossible to buy or replace quickly. In the world of semiconductors, experience is just as important as math and science because small, hands-on details often determine if a factory succeeds or fails.

The company also puts a heavy emphasis on mentorship, ensuring that older experts pass their secrets down to the next generation. This creates a continuous cycle of learning that keeps the company’s skills sharp. By keeping employee turnover very low, TSMC ensures that the hard lessons learned ten years ago are still being used to solve problems today. They don’t rely on flashy “rockstar” hires from outside; instead, they build their own experts from the ground up. This steady accumulation of human knowledge is a quiet but powerful advantage. It allows them to maintain their lead in the industry without needing to make loud announcements or disruptive changes to their staff.

8. Discipline Over Drama

The corporate culture inside TSMC is famously calm and methodical. While Silicon Valley is known for “moving fast and breaking things,” TSMC prefers to move carefully and get it right the first time. Every decision is based on hard data, and the leadership avoids making impulsive moves based on market trends or hype. This level of restraint is a strategic choice that reduces the risk of making a billion-dollar mistake. In a business where a tiny speck of dust can ruin a whole batch of products, being disciplined is a requirement for survival.

This lack of drama is exactly what global customers are looking for in a partner. When a company is building the tech for self-driving cars or life-saving medical devices, they want a supplier that is predictable and stable. TSMC’s employees are trained to value this consistency, ensuring that the company’s culture stays the same even as new leaders take over. By avoiding the chaotic “pivots” that many other tech firms go through, TSMC has created an environment where long-term projects can flourish. Their success proves that you don’t need a loud, charismatic personality at the top to change the world. Sometimes, the most powerful thing a company can be is quiet, focused, and incredibly well-organized.

9. The Silicon Shield

Because TSMC is so important to the global economy, many experts refer to the company as Taiwan’s “Silicon Shield.” Since the world’s most advanced electronics depend on their factories, any disruption to their work would cause a global financial crisis. This reality has turned a commercial company into a key player in international politics. Governments all over the world, from the United States to Europe and China, have a vested interest in making sure TSMC can continue its work without interference. This provides a unique layer of protection for the island where they are based.

Although the company tries to stay out of political arguments, they are fully aware of their strategic importance. They have spent decades planning for every possible disaster, including natural events and geopolitical shifts. This awareness makes them even more cautious and prepared than a typical business. They understand that their responsibility goes far beyond just making a profit; they are essentially keeping the modern world running. By being indispensable to everyone, they have created a situation where the entire world has a reason to keep them safe. This “shield” is a fascinating example of how technology and manufacturing can influence the peace and stability of entire nations without a single shot being fired.

10. Redundancy By Design

Most companies try to be as “lean” as possible to save money, but TSMC takes a different approach by building extra backups into everything they do. They have redundant systems for electricity, water, and even the chemicals used in production. They assume that things will eventually go wrong, and they want to be ready when they do. While this extra equipment adds a lot of cost, it also makes them incredibly resilient. When a crisis happens, like a power outage or a supply chain delay, TSMC can usually keep working while their competitors are forced to stop.

This mindset of “expecting the worst” is one of the main reasons why customers trust them with their most important products. The company would rather be slightly less efficient on paper if it means they can guarantee a steady supply of chips to the world. They perform regular drills to make sure their staff can handle emergencies without panic. Over time, this conservative way of thinking has proven to be a huge competitive advantage. In a world that is becoming more unpredictable every year, having a partner that has already planned for every disaster is worth its weight in gold. This quiet obsession with safety and backups is what allows them to remain the leader in a very fragile industry.

11. Shared Risk, Shared Reward

TSMC does not treat its clients like simple shoppers at a store; instead, it acts as a long-term financial partner. Their contracts are designed so that the factory and the chip designer share both the wins and the losses of a new product. When a customer’s new chip becomes a global hit, TSMC benefits from the high volume of orders. However, if a design has technical issues or fails in the market, TSMC often works closely with the client to absorb some of the stress and fix the problem. This “we are in this together” attitude is very rare in heavy manufacturing.

This deep level of trust removes the usual tension between a buyer and a seller. Because TSMC is financially tied to the success of the chips it builds, its engineers are more motivated to find ways to make those chips better. Since the early 2000s, this model has helped the company build a loyal network of partners who wouldn’t dream of going anywhere else. By the time a product reaches your hand, it is the result of years of shared effort and investment. This interdependence creates a stable business environment that protects TSMC from the sudden ups and downs of the tech industry. It turns a simple business transaction into a powerful, multi-year alliance.

12. Global Supply Harmony

No company is an island, and TSMC understands that it needs a massive network of global partners to stay successful. They work with material suppliers from Japan, machine builders from the Netherlands like ASML, and logistics experts from the United States. To keep this complex system running smoothly, TSMC focuses on “supply harmony,” ensuring that every link in the chain is strong and reliable. In 2022, when global shipping was a mess, TSMC used its influence to keep critical parts moving so that production never stopped. They diversify their sources so they are never too dependent on just one country.

This global reach is a quiet way of protecting the company from regional problems. By spreading their risk across different continents, they ensure that a political shift or a natural disaster in one area won’t bring the whole factory to a halt. They often help their smaller suppliers upgrade their own technology, creating a rising tide that lifts everyone in the ecosystem. This work happens mostly behind the scenes, far away from the news cameras, but it is the reason why your favorite electronics are almost always in stock. TSMC has turned supply chain management into a form of art, proving that being a good neighbor and a steady partner is the best way to stay at the top.

13. Advanced Teams in Arizona

In recent years, the world has realized how risky it is to have almost all advanced chips made in one location. To address this, TSMC began a massive project in 2020 to build a cutting-edge facility in Phoenix, Arizona. This was a major move that cost tens of billions of dollars and involved moving hundreds of expert engineers from Taiwan to the United States. By 2024, the site began moving toward full-scale production of 4-nanometer chips. This move wasn’t about seeking attention; it was a practical step to give global customers an “insurance policy” in case of trouble in Asia.

Building a factory in a new country is incredibly difficult because it requires teaching a new workforce the strict, disciplined culture of TSMC. The company didn’t just buy machines; they sent their best teachers to ensure the “TSMC way” was followed perfectly. This Arizona site helps serve American tech giants like Apple and Nvidia on their home soil, reducing the time it takes to get chips from the factory to the device. It also shows that TSMC is willing to adapt to a changing world where governments want local manufacturing. This expansion proves that while the company is rooted in Taiwan, its vision for the future is truly global and focused on long-term safety for everyone.

14. Fabs By Intelligence

A TSMC factory, or “fab,” is much more than just a building with machines; it is one of the most controlled environments ever created by humans. Every single detail, from the temperature and humidity to the vibrations in the floor, is monitored by artificial intelligence in real-time. Even a tiny change, like a one-degree rise in heat, could ruin a batch of chips worth millions. Because of this, TSMC designs its buildings from the ground up to be smart. They use advanced sensors to catch problems before they even happen, allowing the factory to “heal” itself by making tiny adjustments.

These high-intelligence spaces are the secret to why TSMC can make chips that are so much more reliable than their rivals. Since 2018, they have increasingly used “digital twins,” which are computer versions of their factories that allow them to test new ideas without stopping the real production line. This level of precision is why the world’s most advanced designs are sent to TSMC. They have turned manufacturing into a high-tech science where human error is almost entirely removed. When you look at a massive fab complex, you aren’t just looking at a factory; you are looking at a giant, living computer that is constantly learning how to be more perfect every single day.

15. Quiet Redundancy Networks

While many companies talk about efficiency, TSMC focuses on “redundancy,” which basically means having a “Plan B” for everything. This isn’t just about having extra batteries; it’s about having entire backup systems for water recycling, power grids, and even data storage. In Taiwan, where earthquakes and typhoons are common, these systems have saved the company countless times. For example, during a major drought in 2021, TSMC’s advanced water-saving and trucking plans allowed them to keep making chips while other industries had to cut back or stop completely.

This obsession with backups makes the company look “inefficient” to some investors because it costs a lot of money to keep extra systems standing by. However, TSMC knows that being reliable is more important than being cheap. They run constant “disaster drills” to make sure their employees know exactly what to do if the power goes out or a supply line is cut. This quiet preparation means that when the rest of the world is in a panic, TSMC is usually calm and operational. It is a philosophy that values the long-term survival of the global tech chain over short-term savings. Customers pay a premium for this peace of mind, knowing that TSMC is the most resilient partner on the planet.

16. Learning From Failure

Most companies try to hide their mistakes, but TSMC does the exact opposite. They have a culture that treats every single failure, no matter how small, as a golden opportunity to learn. When a chip comes out with a tiny defect, a team of experts immediately investigates until they find the root cause. They then document everything in a massive digital library so that the same mistake never happens again in any of their factories around the world. This process has been going on for over thirty years, creating a mountain of knowledge that no competitor can catch up to.

This focus on learning helps young engineers become experts much faster. They don’t have to guess how to fix a problem because they can look up how it was solved ten years ago. This “institutional memory” is one of TSMC’s greatest weapons. It creates a compounding effect where the company gets smarter and more efficient every single day. Instead of blaming people for errors, the culture encourages honesty and data-sharing. This approach has turned the company into a learning machine that is constantly perfecting its craft. By the time a new technology is released to the public, it has already been tested and refined through thousands of small lessons learned from past mistakes.

17. Institutional Patience

In today’s fast-paced world, many companies are under pressure to show big profits every three months. TSMC is different because it practices “institutional patience.” They are willing to wait ten or twenty years for a big investment to pay off. When they decided to invest in “EUV” (Extreme Ultraviolet) lithography in the 2010s, it was a massive and expensive gamble that took years to show results. While others gave up or hesitated, TSMC stayed the course. This long-term thinking is why they are now years ahead of the rest of the industry.

This patience also applies to how they treat their customers. They won’t jump on every new trend just to make a quick buck; they only move when they are sure the technology is ready and stable. This makes them a very steady partner for companies that are building the future. Investors who understand TSMC know that the company isn’t looking for a “get rich quick” scheme. They are building a foundation that will last for decades. This calm, patient attitude is a superpower in an industry that is often way too focused on the next three months. It allows them to make the big, hard choices that eventually change the way we live our lives.

18. Quietly Holding the World

If you think of the global tech industry as a giant building, TSMC is the invisible foundation that keeps it from falling over. They don’t make the headlines like the latest AI startup or a famous billionaire, but they are the ones who actually build the tools that make innovation possible. By choosing to stay in the background and focus on manufacturing excellence, they have become the world’s most indispensable company. They handle the hardest parts of engineering so that the rest of the world can enjoy the benefits of modern technology without a second thought.

As the world relies more and more on high-end chips for everything from climate control to transportation, the importance of TSMC only grows. However, this also means that the stakes are higher than ever before. A small mistake at a TSMC fab could delay products for the entire planet. This responsibility is why the company remains so quiet, precise, and disciplined. They know that the world is counting on them to stay focused and get it right. By reflecting on the quiet choices they make, we can see that the most powerful forces in our lives are often the ones we never see. TSMC’s journey shows that true strength doesn’t need to shout to